Tube Laser Cutting Systems 6040

Images of product may not reflect the actual product. Gulf States Saw & Machinery Co., Inc. reserves right to alter product specifications or images at any moment without notice.

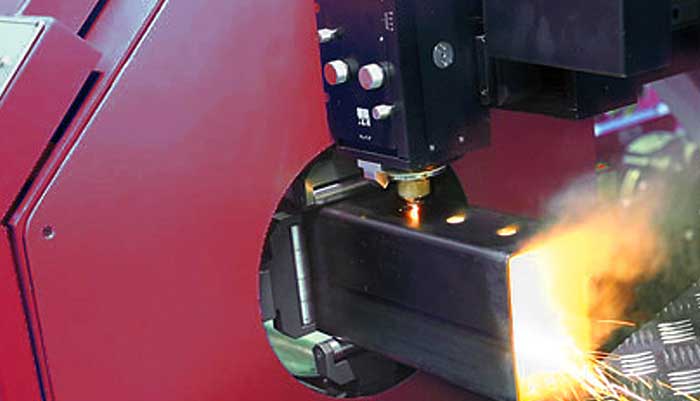

Parts are held using automatic tabbing in FabCreator, as well as a set on jaws on the idler chuck and drive chuck.